|

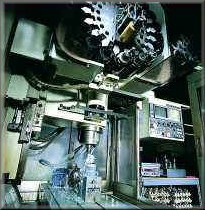

J-Tech's manufacturing

Facility, which include CNC turning centers,

is cutting edge in the connector industry.

J-Tech is a preferred vendor for McDonnell

Douglas, Lockheed-Martin, Bath Iron Works,

Loral (Unisys), Raytheon, General Dynamics

and Ingalls Shipbuilding.

J-Tech's CNC turning and milling

center has made intricate and precise configurations

necessary for locksmith keying from raw metal

and for the unique ramp used in the reverse

bayonet connector. Working with aviation

grade materials (6061-T aluminum, 303,

304 and 316 corrosion resistance stainless

steel), J-Tech's state-of-the-art machines

provide our customers with superior products

at competitive prices.

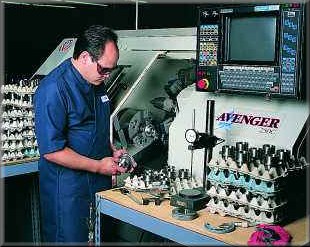

J-Tech's quality

control technologies include statistical process

controls (SPC) and digital measuring, allowing

J-Tech to achieve high quality results while

producing products cost-efficiently. J-Tech's

techniques, processes and tools ensure that

products meet stringent quality control requirements

at every stage of the design and manufacturing

process. J-Tech's customers can be certain

that every connector shipped is of highest

quality and reliability. As a part of the customer's

team, all J-Tech employees put quality first.

|

Skilled programmers design and support

the CNC turning operation to add

precision to the product being

produced. |

|